- Automatic Control System for Water Supply and Drainage Plants, and Water Supply and Drainage Pump Stations

- Water Supply Network Leakage System

- Urban Inland Inundation Monitoring, Early Warning and Emergency Response System

- Municipal Sewage and Water Plant Information System

- Pollution Source Online Monitoring

-

Automatic Control System for Water Supply and Drainage Plants, and Water Supply and Drainage Pump Stations

-

Water Supply Network Leakage System

-

Urban Inland Inundation Monitoring, Early Warning and Emergency Response System

-

Municipal Sewage and Water Plant Information System

-

Pollution Source Online Monitoring

Municipal Sewage and Water Plant Information System

- Categories:Smart Water

- Time of issue:2018-02-25 00:00:00

- Views:0

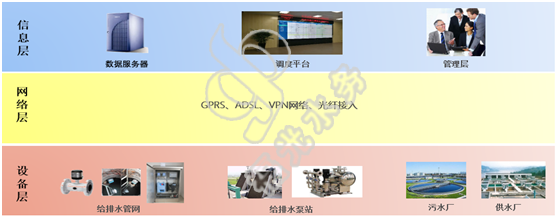

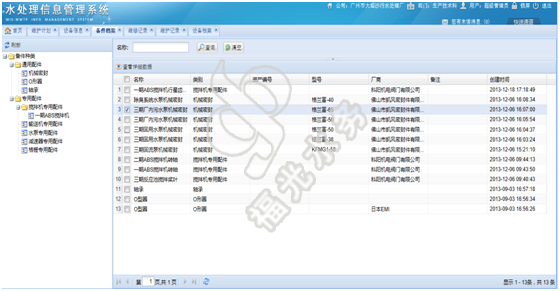

The water information integrated management system is aimed at minimize system operation costs for the water industry on the premise of meeting the standard of water quality. It uses multiple communication technologies to achieve remote distributed data collection, sharing of operation information, real-time production data visualization, automatic management of equipment maintenance, laboratory system management, real-time system failure alarms, intelligent reminders of preliminary accident plans, automatic statistics and generation of production reports and other functions.

System Objective:

Solve the problem of disconnection of corporate information, and information isolated island;

Realize the specialization, standardization and standardized information management models of sewage treatment enterprises and improve their market competitiveness;

Establish enterprise dynamic decision support system to achieve professional and scientific management decisions;

Establish a corporate workflow platform, standardize and normalize work processes, improve management, and achieve effective supervision;

Improve the corporate database of emergency responding plans and knowledge base, improve the knowledge level and quality of personnel, and ensure safe and efficient production;

Establish an intelligent water treatment process model to achieve optimal production scheduling, save energy, and reduce costs.

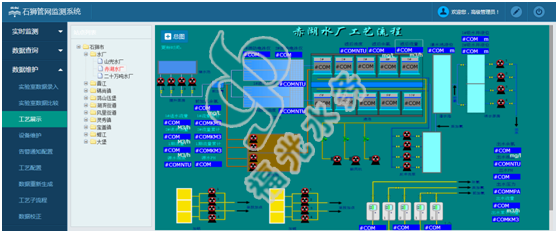

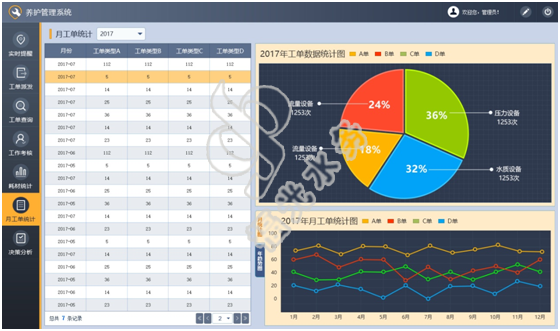

The production scheduling system is a centralized management platform based on the automation system of water plants and pumping stations. It is a comprehensive management system conducting a full range of monitoring, commanding and scheduling to the operation situations of water supply plants, wastewater treatment plants, water supply and drainage pump stations, and water supply and drainage pipe network. Through real-time monitoring and control of the entire process of water plants, pump stations, and pipeline networks, the system can understand the operation conditions of each link; and meanwhile, the production scheduling system records, makes statistics of, and analyzes various data in real time to provide the management layer with data support for the assessment of the entire production situation. Eventually, the system realizes the transparency of the process flow, the openness of production data and the visualization of important links, and provides reliable guarantees for the scientific dispatching and safe production of water supply and drainage work.

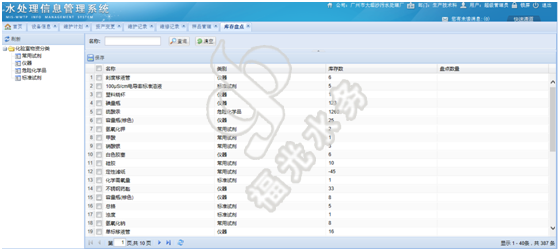

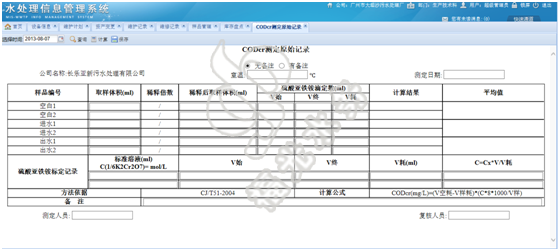

Water quality testing is an important task in the production and operation management of water supply and drainage companies. Providing timely and accurate testing and detection data for operation management personnel to have them master the water quality at all production operation stages and make technological adjustments accordingly will help to control the water quality of the water supply and drainage enterprises and ensure that the water quality meets the standards. The waterworks laboratory management system has formed a set of flexible, easy-to-use, standardized, and highly efficient laboratory information management system with characteristics of the water supply and drainage industry by analyzing and excavating the laboratory management experience of many excellent water supply and drainage companies.

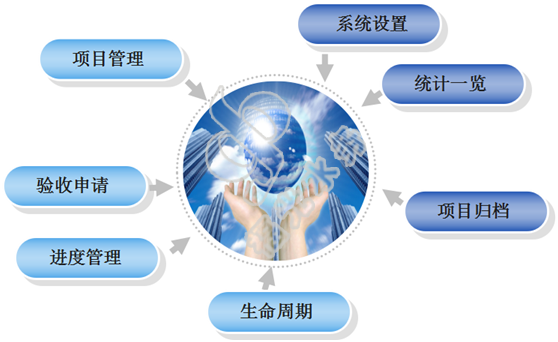

The project management system can help the project manager to use systematic viewpoints, methods, and theories to effectively manage all the work involved in the project under the constraint of limited resources. It plans, organizes, directs, coordinates, controls, and evaluates the entire process from the investment decision of the project to the end of the project, so as to achieve the goals of the project. The engineering management system adopts the dynamic control principle and compares the actual value of project management investment, progress and quality with the planned value, finds deviations, analyzes the causes, and takes measures to achieve the control effect.

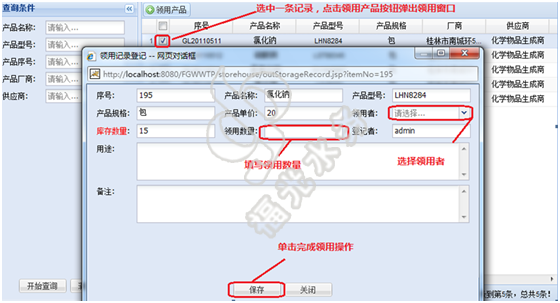

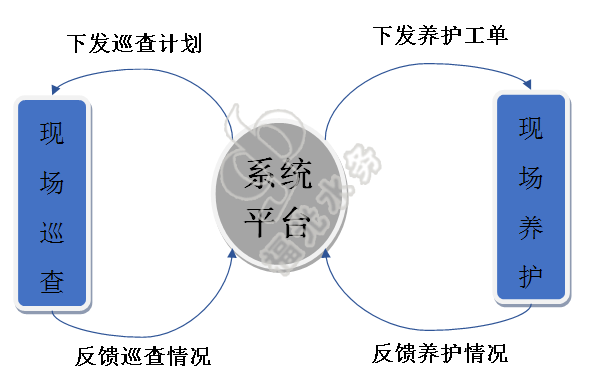

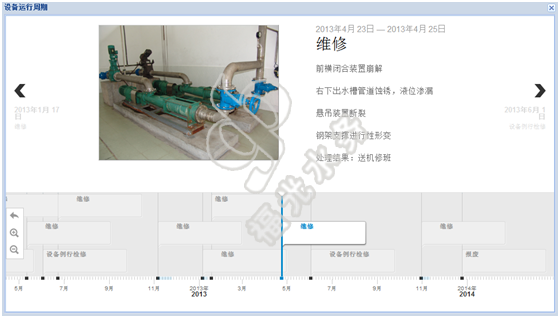

The inspection system relies on the information platform and the inspection terminal to record the inspection status of the inspection personnel. The inspection information is introduced into the inspection system through the on-site terminal, and the system automatically forms statistical reports. The management personnel can keep track of the situation of personnel in corresponding positions and combine electronic maps to view equipment distribution, inspection trajectories, and distribution of outliers, thereby realizing informationization, digitization and network-based management of inspection work. Maintenance management work orders are from work orders in systems such as inspection systems and call centers. When the maintenance system automatically obtains the work order, the management personnel selects the maintenance personnel at the location of the work order according to the position of the work order, and distributes the work order contents to the corresponding maintenance personnel.

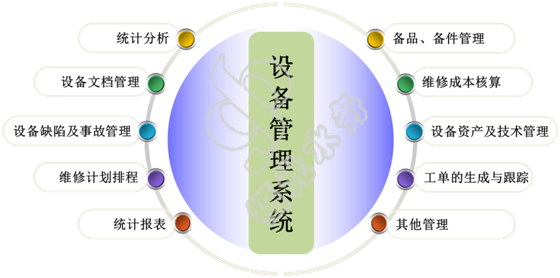

Through the whole life cycle management of various types of equipment in waterworks, sewage treatment plants, and pump stations at all levels, the system meets management personnel’s management demand during equipment procurement, use, storage, maintenance, operation, inspection, maintenance, and scrapping. It implements equipment status tracking, automatically integrates the entire process of data records of the equipment, keep abreast of equipment service condition and technical status, ensures the normal operation of the equipment, effectively reduces equipment failure rate, reduces cost, and achieves maximum economic benefits.

Scan the QR code to read on your phone

Mainly engaged in the distribution of environmental monitoring instruments and meters, as well as the integration and operation and maintenance of environmental monitoring systems; Research and development, production, and sales of environmental monitoring instruments;

Copyright ©2023 Fuzhou Fuguang Water Science&Technology 闽ICP备12013341号-2 Powered by saa

Follow Fuguang Water

Official Taobao Store

Fuzhou Fuguang Water Science&Technology Co.,Ltd